Sound absorption

By sound absorption, we mean a reduction in the acoustic energy, in other words a reduction in the prevailing sound waves. In physical terms, a sound wave strikes a surface and is "swallowed" by the surface and transformed into heat energy. In order to create the right acoustic conditions in a room, there must be a good balance between absorbent and reflective materials. In modern architecture, reverberant glass and concrete surfaces are frequently used - the ceiling is often the only surface here that can absorb sound.

Degree of absorption and reverberation time

The degree of absorption α indicates the percentage of acoustic energy absorbed. The value α=1 means that all the energy is absorbed, i.e. converted into heat. A value of α=0 means that all the acoustic energy is reflected. The relevant frequency range for room acoustics lies between 125 Hz and 4000 Hz.

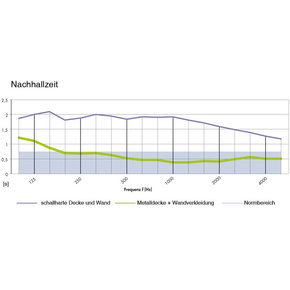

The reverberation time is the oldest and best known room acoustic criterion. It is defined as the time in which the sound pressure level decreases by 60 dB after switching off the sound source. Depending on the intended use of the room, there is a specific ideal reverberation time, e.g. 0.6 s for school classrooms. These minimum requirements are defined in DIN 18041 "Acoustic quality in small to medium-sized rooms".

Perforated surface

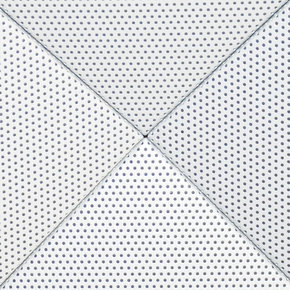

Thanks to their minimum material thickness of approx. 0.7 mm and the perforation, metal ceilings can be categorised as porous absorbers. The acoustic energy is transformed into heat by friction and thus absorbed. This is additionally influenced by the suspension height of the ceiling and the type of lining on the rear side of the tile.

The great advantage of ceiling tiles compared with many other absorbers is that they absorb sound over a wide range of frequencies. The entire relevant range from 250 Hz to 4000 Hz is therefore covered. Hence, ceiling tiles are suitable for absorbing sound with both deep and high tones.

further reading:

Fleece and linings

FURAL metal ceilings are mostly equipped with a sound-absorbing acoustic fleece. Depending on the perforation, absorption levels of up to αw = 0.95 can therefore be achieved. The standard colour of the bonded acoustic fleece is black, but other colours, such as white, grey or green, are also available.

Linings made of glass wool or rock wool further improve the sound absorption values. In order to ensure a high standard of hygiene, the linings can also be welded into thin PE films.