Pricing out CO2 in offers - showing alternatives and creating transparency

Many developers or developers' employees want to be part of the solution to climate change. They want to emit less CO2. These meaningfully critical customers are the future and this group of people is growing.

Large construction projects are already being certified according to various assessment systems. The criteria according to DGNB, LEED, BREEAM, or OGNI focus differently on the building life cycle with construction, utilisation and dismantling. For Fural's customers, the processors of metal ceiling systems, this meant complex documentation requirements.

Fural Metalit Dipling wants to create transparency and offer alternatives with regard to CO2 emissions. How much CO2 is released when a Fural product is manufactured using standard steel? What CO2 savings are possible by using greentec steel and what additional costs arise? We want to simplify the documentation requirement as much as possible. We want to inform, raise awareness and support our customers.

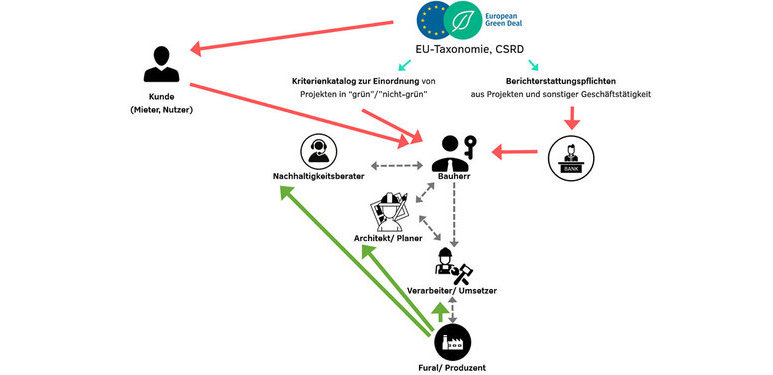

Overview - Green Deal, EU-Taxonomy, CSRD

1. Context – Green Deal, EU-Taxonomy, CSRD - everyone has to contribute

- Five years ago, the Green Deal was agreed in the EU with the aim of achieving climate neutrality by 2050.

- Companies (including medium-sized companies) are obliged to prepare sustainability reports from 2026, which are regulated in the CSRD.

- The EU taxonomy sets out requirements for the classification of sustainable economic activities (particularly for developers). The EU taxonomy includes new construction projects as well as refurbishment projects and classifies projects as "green" (=compliant) and "non-green" (=not compliant).

- As a result, there is double pressure on property developers: Large customers (tenants), who are also obliged to report compliance with appropriate standards (e.g. green leases), banks are obliged to provide financing for green investments (e.g. green asset ratio).

2. Role

- Procurement practices are changing: In addition to price, new metrics are becoming increasingly relevant (CO2 in construction and operation as well as recyclability). Processed products must carry certain declarations that provide information about the CO2 footprint = EPD.

- Supplying companies are requested to provide additional information. The availability of sufficiently "green" products can become a decisive factor (if developers need points for certifications/ have to fulfill EU Tax criteria)

3. Chance

- Fural assesses the products ecologically and measures CO2 emissions extensively. In addition to the existing, selfdeclared EPD, a third-party verified EPD has been commissioned.

- In addition, Fural already offers lower-CO2 products. Any interest from developers can be met immediately (Supplements).

- Fural is not reducing its existing offers/ strengths (quality, reliability, price), but is expanding its range for processors.

Basis

Sustainable building is a key issue these days. The EU Green Deal aims to achieve climate targets by, among other things, making the construction industry, which is responsible for around 40% of global greenhouse gas emissions, more sustainable. This includes complying with the 4Rs: reduce, reuse, recycle and recover. These principles reduce material consumption, promote the reuse and recycling of building materials and emphasise the importance of closed cycles.

Metals (steel, aluminum, copper) are particularly important here because they have an established recycling process and are almost 100% recyclable. Today and in the future, metals are bought from scrap dealers and are therefore considered sustainable materials.

Building certifications such as LEED, DGNB or BREEAM assess buildings in terms of their environmental impact, among other things based on the products they contain.

Important 1: Building certifications are becoming increasingly important for developers and investors as banking institutions, purchasers and employees place more and more value on these certifications. Developers are required to report to or be increasingly "green" AND green is measured in CO2.

Environmental product declarations (EPD)

EPDs contain an objective assessment of the environmental impact of products and evaluate the use of energy and resources as well as contributions to the greenhouse effect, acidification, over-fertilisation, destruction of the ozone layer, smog formation and land consumption. Technical properties such as product service life, thermal conductivity and sound insulation are also taken into account.

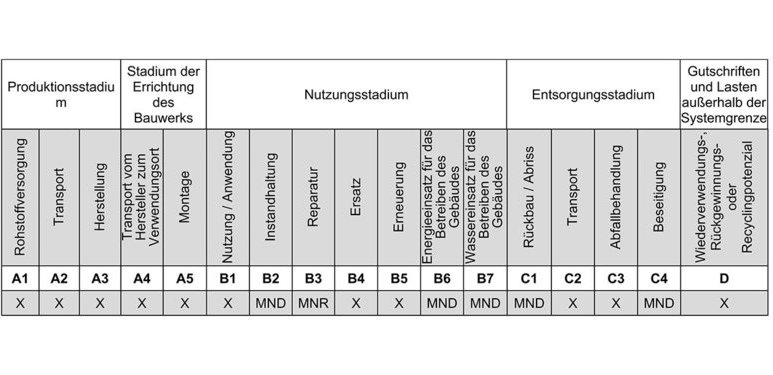

EPD considers the entire product life cycle and divides it into five stages: production (raw material extraction and processing), construction (installation of the product in the building), utilisation (use of the product over time), end-of-life (dismantling, recycling or disposal), new life cycle – the start of a new life cycle for recycled products.

In the current version of the EPD, the manufacturer must specify the first phase (production stage); further phases are voluntary.

Furthermore, the producer can specify the duration of the product life cycle himself or it can be specified according to the table of the Federal Institute for Research on Building, Urban Affairs and Spatial Development. For some products, the stated service life must be critically examined as it does not correspond to the actual service life. This significantly embellishes the environmental product declaration, as the assessment period is extended.

Important 2: EPD is the basis for any documentation for customers. In EPDs, ceiling systems made of gypsum or mineral fibre are specified with "up to 50 years", metal with "over 50 years service life". Practice shows: Gypsum and mineral fibre ceilings do not have a service life of 50 years - the figures here need to be critically examined.

Equivalent units, such as CO2 equivalence (CO2e), are used in an EPD - they represent different substances in a common unit of measurement. For example, greenhouse gases such as methane (CH4 - 28 times more harmful than CO2) and nitrous oxide (N2O - 265 times more harmful than CO2) are expressed in CO2 equivalents. This makes it possible to quantify and compare all greenhouse gas emissions of a product in a single unit of measurement.

Important 3: CO2 equivalence (CO2e) in kilograms becomes a unit of measurement like euros. Individuals are starting to calculate in euros and CO2e.

Sustainable metal ceilings

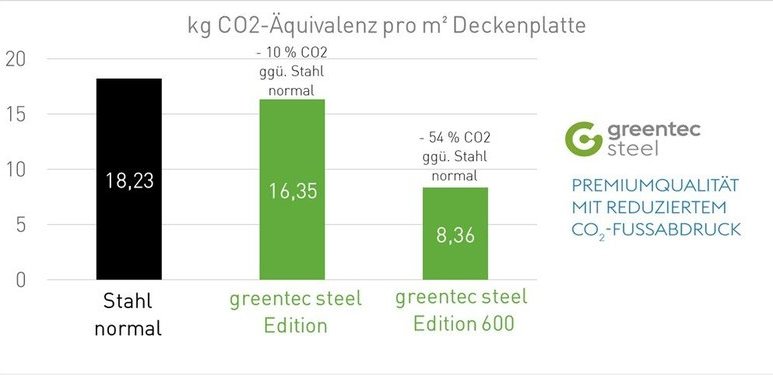

Voestalpine, Austria's only crude steel producer and a global pioneer in environmental protection, is actively committed to more sustainable steel production. Thanks to intensive savings in production, Voestalpine offers products with reduced CO2e emissions:

- Greentec steel Edition with 10% CO2e savings in steel production and

- Greentec steel Edition 600 with 75% CO2e savings

Important 4: Greentec steel Edition (10 % CO2e-savings) and Greentec steel Edition 600 (75 % CO2e-savings) enable the production of metal ceilings with up to 66 % less CO2e emissions compared to metal ceilings with normal steel.

Fural, as a long-standing partner of voestalpine, offers sustainable metal ceilings made from these steel types and consequently also reduces their CO2e footprint - by up to 66% depending on the type. This calculation is based on voestalpine's EPD and the internal gas and electricity consumption for the production of our metal ceiling tiles at the respective locations (Gmunden, Hungen, Büron).

When purchasing greentec steel, voestalpine issues a certificate for its purchase, which is checked and monitored by the independent sustainability consultancy Daxner & Merl.

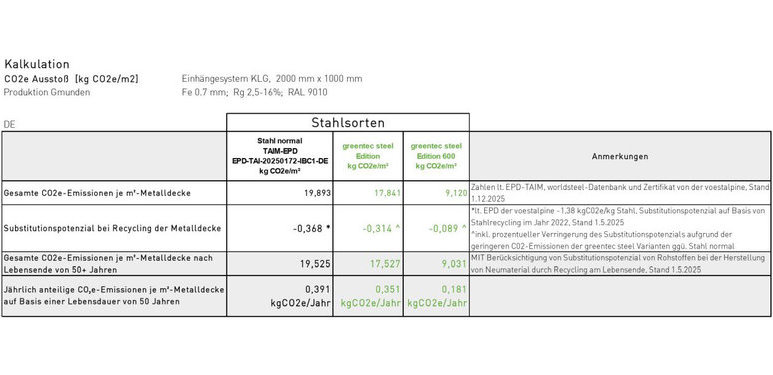

Explanation of calculation elements of the Fural Metalit Dipling calculation (Database TAIM EPD-TAI-20250172-IBC1)

The three variants of steel types are shown in the offer. “Normal steel” refers to the industry average (worldsteel EU average). “Greentec steel Edition” and “greentec steel Edition 600” contain those steel types that, thanks to emissions savings in the CO2 balance account, only produce 2.13 kg (Greentec steel Edition) and 0.6 kg (Greentec steel Edition 600) of CO2. equivalents per kilogram of steel compared to commercially available galvanised sheet steel (2.49 kg).

The calculation of the CO2 equivalence is based on the figures from the EPD 'EPD-TAI-20250172-IBC1' of TAIM (TAIM = Association of Industrial Metal Ceiling Manufacturers).

Depending on the type of steel selected, the equivalent CO2 emissions decrease.

Offer calculation

The following explains the figures included in the offer. In the offer you will find a calculation based on average CO2e emissions per m² ceiling area with different types of steel, their calculated total emissions for the offered m² ceiling area (100 m² assumed) as well as the improvement of the sustainable Greentec steel types compared to normal steel.

|

Values for 1 m² metal ceiling with Ø 8.45 kg/m²: |

Ø kg CO2e/m² |

Improvement vs. normal Steel |

Ø additional price per m² |

kg CO2e on 100 m² |

Substitution potential* when recycling 100 m² at the end of its life |

|

normal steel |

Ø 18,227 |

|

|

1.822,7 |

Ø –74,2 kg CO2e |

|

greentec steel Edition |

Ø 16,647 |

- 10 % |

+ ca. 5 % |

1.664,7 |

Ø – 63,5 kg CO2e |

|

greentec steel Edition 600 |

Ø 8,356 |

- 54 % |

+ ca. 10 % |

835,6 |

Ø – 17,9 kg CO2e |

* If the dismantled metal ceiling is fed into the recycling process, the substitution potential (numerical values according to Module D of the EPD) is activated. This reduces the amount of raw material required for new production. This process forms the closed cycle of metal recycling. The substitution potential is based on steel recycling from 2024 and the proportion of steel recycling in voestalpine's new material (basis: 2024).

If Greentec steel Edition is used with 10 % less CO2e emissions compared to conventional hot-dip galvanised steel strips, the equivalent CO2 emissions including further processing / production at Fural Metalit Dipling are reduced by 10 With greentec steel Edition 600, even by 54%, from 18.223 to 8.36 kg CO2-equivalent per m² of ceiling panel.

The average CO2e emission values per m² of ceiling tiles used in the quotation calculation were determined based on four different and very frequently used systems:

|

|

normal steel kg CO2e/m² |

greentec steel Edition kg CO2e/m² |

greentec steel Edition 600 kg CO2e/m² |

|

KQK 625 x 625 x 0,5 mm, Rg 2,5 - 16 %, steel, 1,8 kg |

15,188 |

13,622 |

6,963 |

|

KLG 1.200 x 600 x 0,6 mm, Rg 2,5 - 16 %, steel, 3,7 kg |

17,935 |

16,085 |

8,222 |

|

KLG 2.000 x 1.000 x 0,7 mm, Rg 2,5 - 16 %, steel, 11,3 kg |

19,893 |

17,841 |

9,120 |

|

KLG 2.500 x 1.200 x 0,7 mm, Rg 2,5 - 16 %, steel, 17 kg |

19,893 |

17,841 |

9,120 |

|

Ø CO2-emissions / m² metal ceilings with Ø 8,45 kg/m²: |

Ø 18,277 |

Ø 16,347 |

Ø 8,356 |

Using the KLG 2,500 x 1,200 x 0.7 mm cassette, the more precise calculation of CO2e emissions is to be explained: Based on the EPD data, the following results are obtained for this cassette dimension:

The substitution potential of the Greentec steel Edition and the Greentec steel Edition 600 results from the percentage reduction in CO2e emissions compared to normal steel. Using greentec steel Edition as an example: greentec steel Edition emits 2.13 kg CO2e/kg steel compared to 2.49 kg CO2e/kg emitted by normal steel, i.e. 14% less CO2e/kg steel. When substituting new material, the greentec steel Edition therefore has 14% less substitution potential, taking into account the recycling rate at voestalpine.